e-Platch™: Smart inspection support service

Make factory inspections wireless and visualize data with "e-Platch™" for

improved efficiency!

This inspection systems can be easily introduced via retrofitting, and they help to maximize the efficiency of factory patrol inspection work.

For equipment-related departments in the manufacturing industry that face issues such as the following:

- There are many measurement instruments and meters over an extensive site, and patrol inspections depend on individual skills.

- Human errors occur frequently due to paper-based inspection work.

- Unable to notice the occurrence of abnormalities immediately.

- Due to blind spots of radio wave, it is difficult to introduce wireless services.

- Occupational accidents occur due to inspection work.

Improve the efficiency of factory inspection work

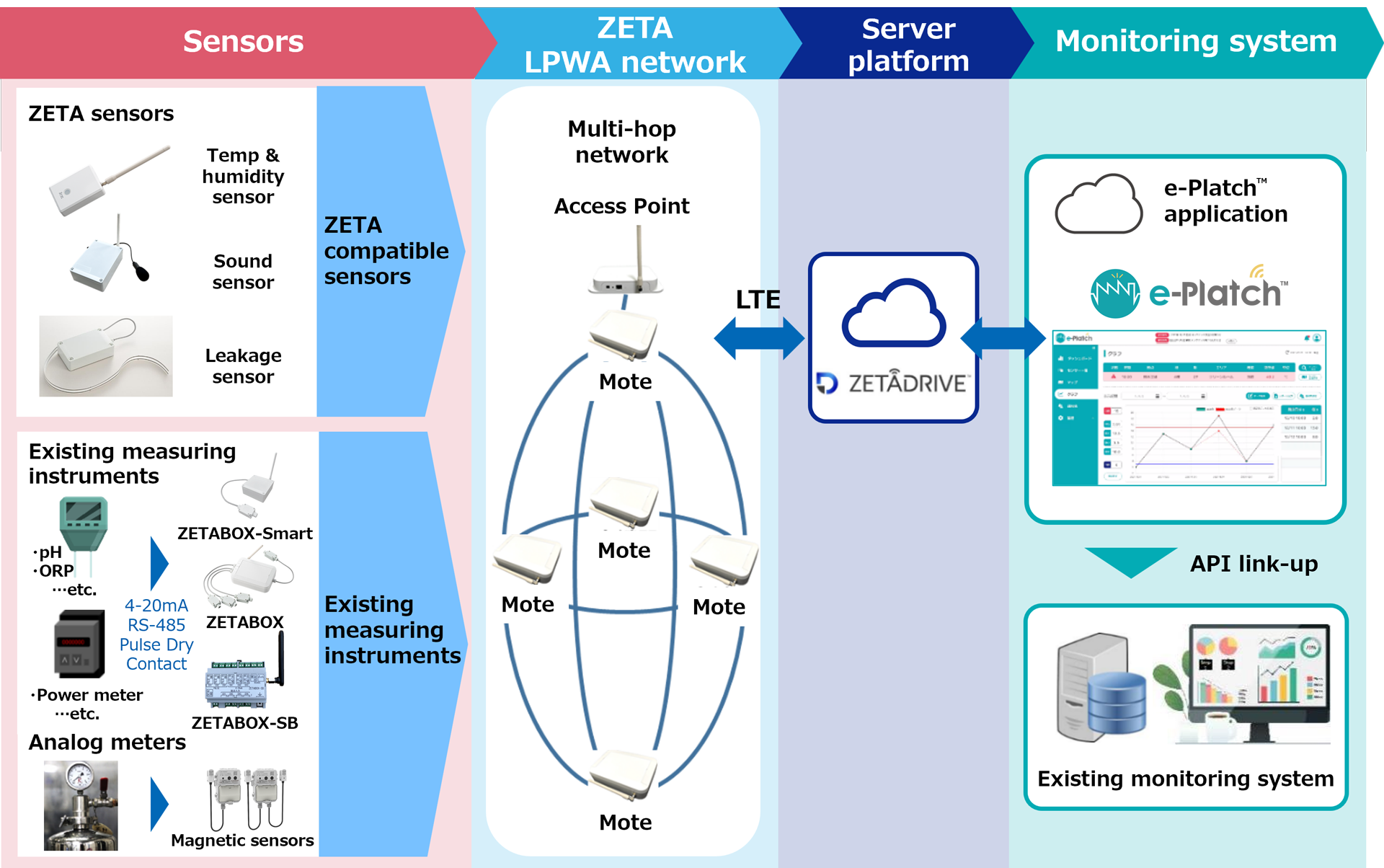

e-Platch™ is a system that uses wireless communication to automatically gather and visualize various kinds of data necessary for inspection work. The system utilizes an application to automatically send users alert emails when thresholds set for each sensor are exceeded, which can reduce the workload for inspections.

e-Platch™ introduction

Capable of handling many items of factory inspection

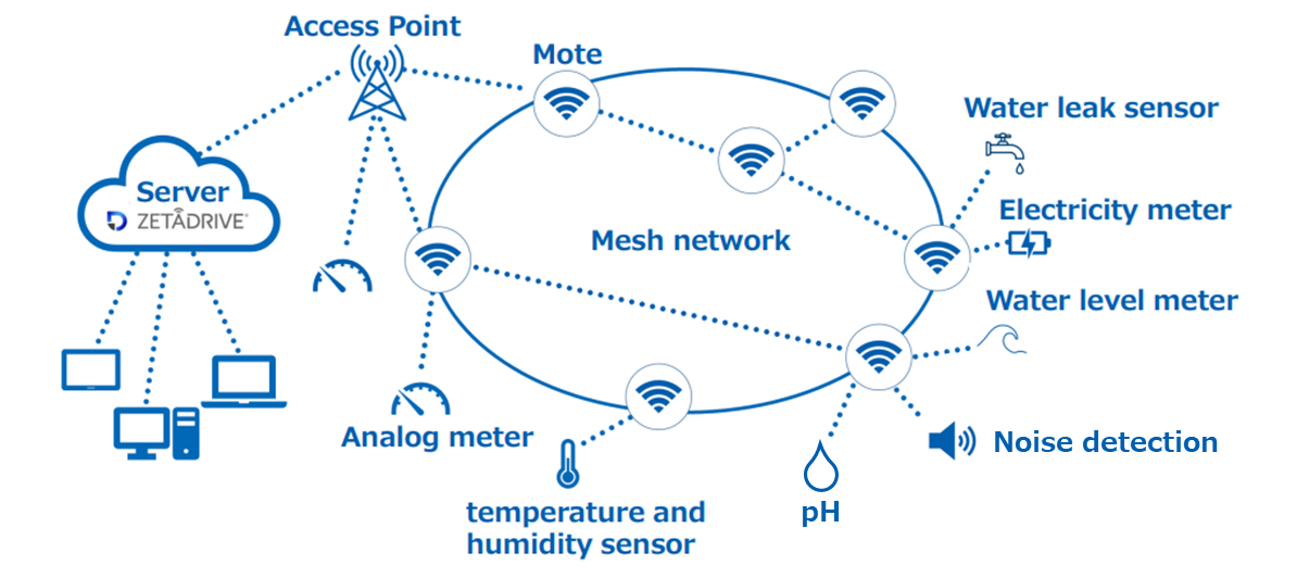

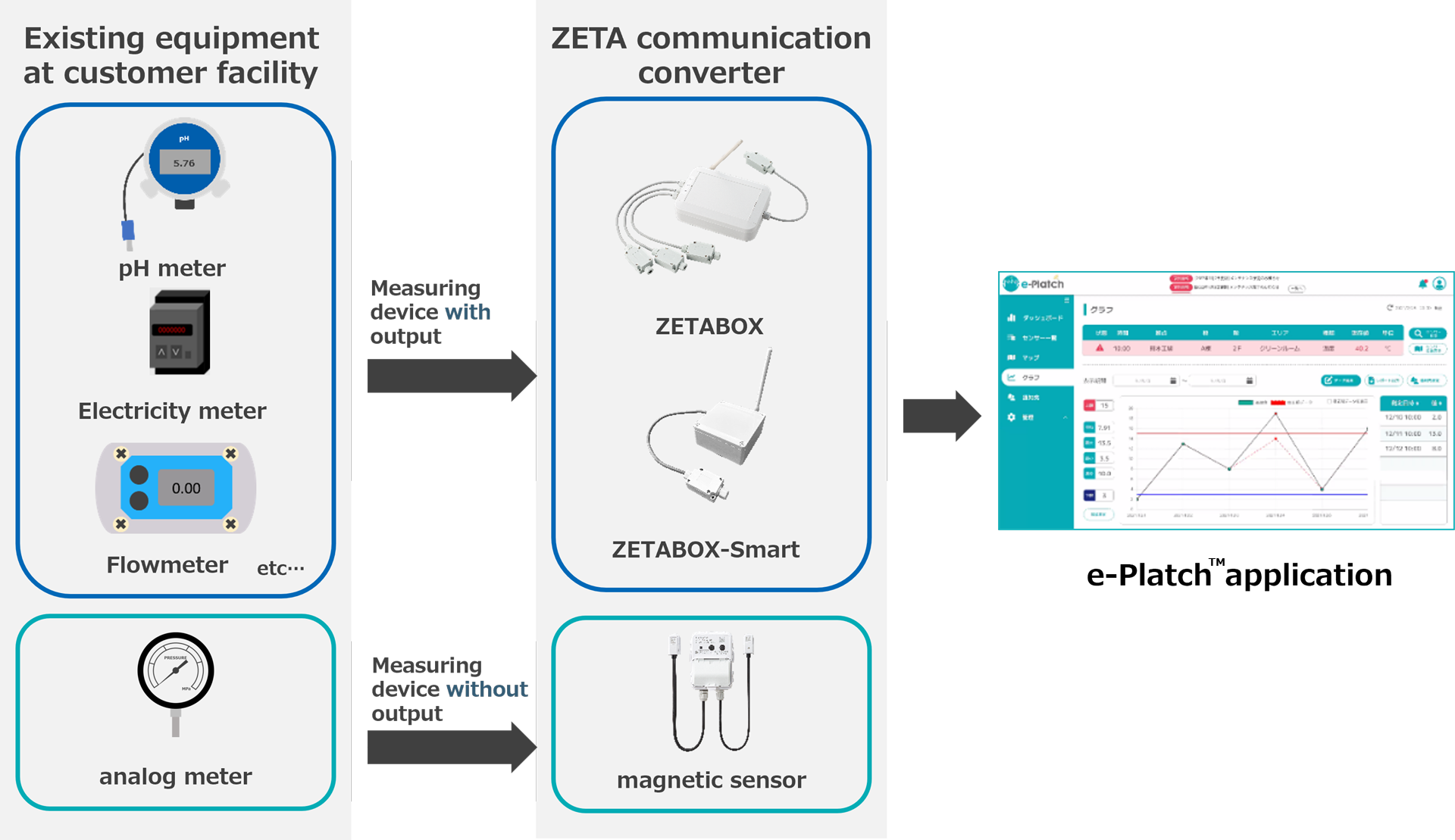

Analog meters and pressure gauges are key obstacles standing in the way of shifting to IoT systems, but our system uses magnetic sensors to read the angles of needles, enabling the automatic reading of analog meters.

In addition, our system uses ZETABOX, which makes data from measurement instruments with 4-20 mA, RS-485 (Modbus RTU), pulse, or dry contact outputs wireless, includes ZETA-compatible sensors, and handles many inspection items, including humidity, abnormal sounds, water level, energy, etc.

e-Platch™ features

-

1

Networks you can connect to anywhere: ZETA networks

Thanks to the use of ultra narrow band communication as well as motes (battery-operated repeater) that do not use power sources, networks can be built anywhere—even in places that radio waves have trouble reaching, such as in the shadows of buildings and underground. ZETA can easily communicate data even in places where other standards would struggle, making these networks optimal for IoT in factories facing inspection-related issues.

- Ultra narrow band communication is strong against radio wave interference and enables communication with a line of sight of 10-20 km.

- Motes (battery-operated repeater) can be installed to build networks that cover entire facilities, including both indoor and outdoor areas.

- Various kinds of sensing are possible thanks to ZETA-compatible sensors that can be battery-powered.

-

2

Retrofittable converters that can make existing equipment data wireless

Existing measurement instruments and analog meters can continue to be used, which means there is no need for large amounts of capital investment. Magnetic sensors achieve remote monitoring by reading the angles of needles in round analog meters and pressure gauges. ZETABOX makes data from measurement instruments with 4-20 mA, RS-485 (Modbus RTU), dry contact, or pulse outputs wireless. Since our system utilizes magnetic sensors and ZETABOX, it lowers the barriers to introducing the inspection system to factories.

-

3

A dedicated application specifically for factory inspection work

This application includes many functions ideal for factory inspection work, such as displaying graphs of data, setting thresholds, notifying users when abnormalities occur, outputting simple reports, importing floor map images, and setting locations of installed sensors.

Examples of cost reduction improvements with e-Platch™

By implementing e-Platch™, it becomes possible to grasp the total amounts of resources used within the factory, such as chemicals and electricity. By understanding the required quantities of resources for factory operations, the reduction of unnecessary usage can be realized.

Case1: Annual savings of JPY 1.4 million in chemical usage expenses.

Measures were needed to address the increasing costs and environmental impact of daily chemical use. By accurately measuring chemical usage with e-Platch™ and analyzing the data, significant waste was discovered. Based on the collected data, the optimal chemical input amount was identified, leading to successful cost reduction.

Case2: Annual savings of JPY 14 million in electricity usage expenses.

Along with the soaring electricity prices, there was a need to control usage, but it was difficult to determine how much electricity was being used on individual lines. By introducing e-Platch™ and measuring the electricity consumption per line, waste was discovered, leading to the successful control of electricity usage.

Comprehensive security system

We have obtained certification for cloud security under the international standard ISO27017, and we are providing services under secure conditions that conform to global security standards.

Voices from users of the e-Platch™ factory inspection system

By offering various proposals specific to the needs of each customer, we can help to resolve previously unsolvable issues.

Voice 1: A major material manufacturer

Given the cost and work involved, buying all the necessary equipment at once would have posed a challenge, so we started small and introduced equipment little by little. After several years, we were able to introduce the entire system!

Voice 2: A semiconductor manufacturing equipment company

An employee had to work on holidays to check the humidity in the cleanroom, but remote monitoring using e-Platch™ was able to handle inspections instead, improving working conditions!

Voice 3: A facility management company for a major electronics manufacturer

Although we were checking the sounds generated by air conditioning equipment, there were accuracy variations from worker to worker. However, acquiring data made it possible for anyone to detect abnormalities!

Steps toward introduction

Following a consultation with our clients, we will manage the entire process from proposal to operation.

Frequently

asked questions

-

QCan the equipment be installed outdoors?

AYes. Most of the equipment meets IP65 to IP67 standards, allowing for outdoor installation.

-

QWhat is the minimum data transfer interval?

ABasically, it is one hour or more.

-

QCan we connect data to our existing system using APIs?

AYes.

*Note: Regulations differ depending on the country, so we may be unable to conduct sales of this solution outside of Japan.